Applications for Permanent Magnetic Materials

Calculate the following, based on your actual alloy chemistry:

Application Examples

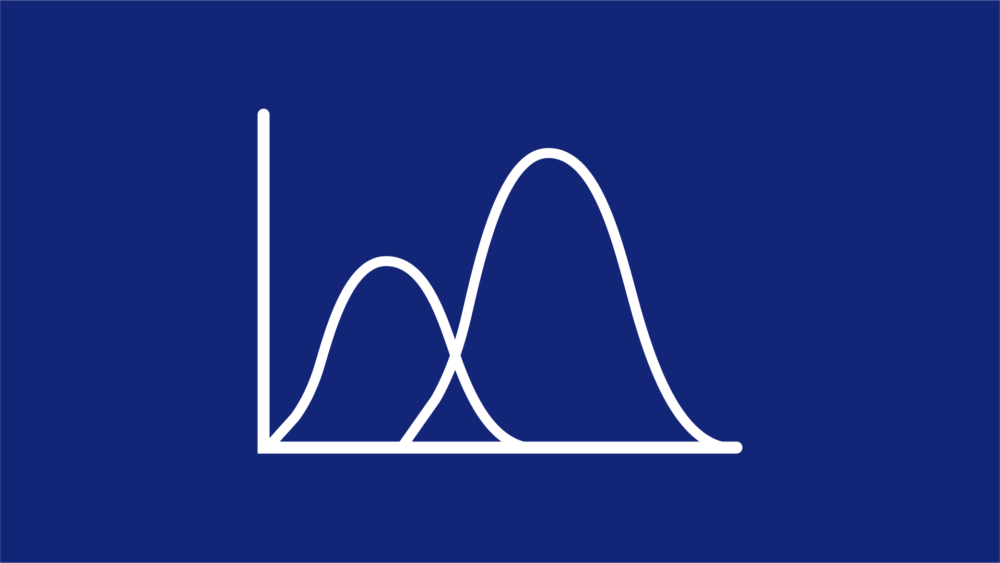

Prediction of Curie Temperatures

The Curie temperature (Tc) is a critical temperature, above which certain materials lose their permanent magnetic properties. It is therefore one of the most important properties for permanent magnetic materials. As a result, developing new alloys that extend the temperature range of practical usage along with good structural stability is of strong interest.

The Curie temperature can be predicted using Thermo-Calc as a function of chemical composition. A comparison is made in the plot here against collected experimental data for a number of given permanent magnetic alloys.

Prediction of Thermophysical Properties for Permanent Magnets

Several of the permanent magnets (such as Nd-Fe-B permanent magnets) are processed via powder metallurgy. To ensure a fully dense and defect free material, it is useful to have a good wetting behaviour of the Nd-rich liquid phase, which can be directly studied using surface tension of the melt.

Many thermophysical properties are included in the Permanent Magnet Database, which means viscosity, surface tension, electrical resistivity, and thermal conductivity can be calculated as a function of composition and temperature in Thermo-Calc. The plot here is a validation example comparing experimental and simulated surface tension for an Nd-Fe-B-Ga alloy from Noguchi et al., 2021. Ga is added as a quaternary element to the Nd-Fe-B alloy for increasing coercivity and improving wettability of the resulting material.

Learn more about Applications to Permanent Magnetic Materials

Multiscale understanding of microstructural evolution during directional solidification of magnetostrictive Tb-Dy-Fe alloys

A collection of examples that demonstrate the validity and calculation abilities of the TCPMAG database.